Injection molding is the pillar of mass production of phone cases. For both phone case manufacturers and buyers, choosing the right molding process is the first step to creating products that stand out in the highly competitive market.

In this guide, we will break down the most effective injection molding techniques for phone cases, so that you can make an informed decision and work with the right phone case manufacturer to meet your needs.

What Is Injection Molding?

Table of Contents

ToggleThe core of injection molding is to melt plastic materials (such as TPU, PC, or ABS) and inject the molten resin into a custom mold under high pressure. Once cooled, the mold opens, revealing a finished phone case (or component) with precise dimensions and consistent quality.

For phone case manufacturers, this process is unparalleled for three key reasons: it can be mass-produced with minimal waste, provides consistent results in thousands of units, and supports the complex designs that consumers like.

Unlike 3D printing (which is highly suitable for prototyping), injection molding strikes a perfect balance between efficiency, cost, and design versatility, making it the preferred choice for phone case manufacturers serving global markets such as Europe and the United States.

Key Injection Molding Types

1. Thermoplastic Injection Molding

Thermoplastic injection molding is the main force in the mobile phone case industry, and there are good reasons for this. It uses heat-resistant and recyclable materials such as TPU (soft and shock-absorbing), PC (hard and durable), and ABS (lightweight and impact-resistant), all of which comply with European and American environmental protection standards such as RoHS and REACH.

This process is good at producing large quantities of consistent protective cases: think of transparent protective cases, basic solid-color shells, or budget-friendly shockproof cases.

For phone case brands, the advantages are obvious: lower production costs, faster delivery times (which are crucial for taking advantage of seasonal trends), and materials that resonate with environmentally conscious consumers. Cooperating with a phone case manufacturer that can provide reliable and compliant injection-molded phone cases on a large scale is a reassuring choice.

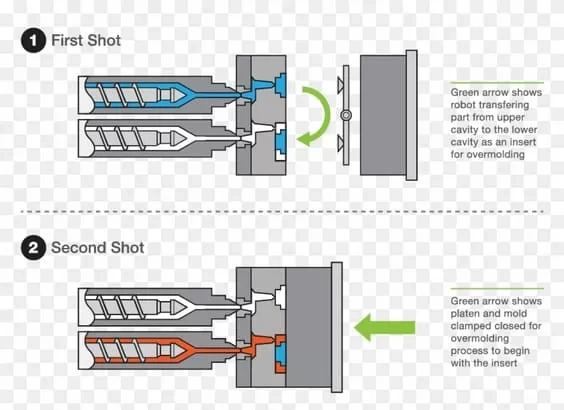

2. Overmolding

If you want to add texture, grip, or functional contrast to your phone cases, overmolding is your choice. This technology involves forming two different materials in a single process – for instance, pairing a hard PC backplane with a soft TPU frame.

The overmolded phone case combines the advantages of two features: durability and user-friendliness. They are suitable for mid-range to high-end shockproof shells with ergonomic designs.

This means for you that the product has a stronger market differentiation – consumers are willing to choose those that feel high-end and can solve practical problems (such as anti-slip grip!).” The products pay a higher price. A manufacturer specializing in custom phone cases can help you transform your unique ideas into practical and marketable products.

3. Two-Shot Injection Molding

Two-shot injection molding is the secret to manufacturing eye-catching, fashionable phone cases. This advanced technology utilizes a single mold to inject two different colors or materials within a single cycle, eliminating the need for secondary assembly (such as glue or paint).

So, what was the result? Seamless two-color design, gradient effect, or permanently embedded brand logo (without peeling or fading). Imagine a shell that offers bold color blocks, subtle metallic tones, or matching brand tones – these details make your product stand out on store shelves and e-commerce lists.

For you, secondary molding means higher perceived value, lower production costs (when the quantity you order is large enough), and designs in line with global fashion trends.

4. Insert Molding

For buyers who focus on functional and feature-rich phone cases, the insert molding process is a transformative technology. This process involves placing pre-manufactured components (such as metal magnetic sheets, plastic buttons, or waterproof gaskets) into molds before injection molding.

The molten plastic combines with the insert to form a single integral product – without loose parts or fragile connections. Insert molding is highly suitable for special applications: magnetic charging housings, durable outdoor housings with reinforced corners, or water-tight models designed for active consumers.

As a buyer, this technology enables you to enter niche markets (which is a huge opportunity in Europe and America) and offer products that can address the specific needs of particular users. When reviewing mobile phone case manufacturers, ask them whether they have insert molding capabilities- Can they handle complex components and ensure consistent bonding effects?

5. Micro Injection Molding

Precision is very important, especially for high-end phone cases designed for flagship devices. Micro-injection molding is a specialized technique for producing tiny, complex components with extremely high precision – think of lens protection rings, ultra-thin edge trims, or small trims.

These details may seem insignificant, but they have a significant impact on perceived quality: a watch case with a perfectly fitted lens ring feels more sophisticated than one with gaps or rough edges. Micromolding is an ideal choice for ultra-thin cases, luxurious designs, or custom-made cases for specific mobile phone models (where every millimeter counts).

For you, this means working with a phone case manufacturer that prioritizes precision to win over picky consumers who demand perfection.

How to Choose the Right Injection Molding Type

Faced with so many choices, how do you select the appropriate injection molding type based on your own needs? The following is a practical decision-making framework:

1. Start with your product goals: Are you targeting budget-oriented consumers (thermoplastic molding) or luxury buyers (two-shot or micro molding)? Do you need functional features (insert molding) or design highlights (overmolding)?

2. Consider your production volume: Thermoplastic materials and overmolding are best suited for large orders, while two-shot or micro molding may result in a higher minimum order quantity (MOQ) due to dedicated molds.

3. Keep in line with market trends: Consumers in Europe and the United States prefer eco-friendly materials (giving priority to thermoplastic materials using recyclable resins) and unique designs (two-shot or overmolding). Study the best-selling products on platforms such as Amazon, Etsy, or local retail chains.

4. Check compliance: Ensure that the phone case manufacturer uses materials and processes that meet European and American standards (for example, food contact parts such as phone grips need to comply with ROHS, REACH, and FDA standards).

5. Balancing cost and value: High-tech processes (such as two-color injection molding or micro molding) have higher mold costs in the early stage, but the profit margin can be increased through premium pricing.

Remember, the best phone case manufacturers will work with you to make the injection molding process fit your goals – not just promote their most profitable options.

YG – Your Trusted Phone Case Manufacturer

At YG, we are not merely a phone case manufacturer – we are your partner, bringing high-quality market products to the global market. With over 30 years of experience serving global buyers, we have mastered the above five injection molding technologies.

We have the ability to handle all business from small-batch custom orders to large-scale mass production. Our advantages lie in:

- Fully equipped: We have the most advanced injection molding machines, including dual-shot and micro molding systems, to turn your ideas into reality.

- Standard-compliant materials: We only purchase high-end recyclable plastics that comply with RoHS, REACH, and other regional standards – so you can sell with confidence.

- Customization flexibility: Whether you need a two-tone shell, functional design, or precision micro-mold components, our team will work with you to perfect every detail.

- Outstanding track record: We have collaborated with dozens of global buyers to create the best-selling injection-molded phone cases, ranging from budget-friendly basic to high-end, trend-setting designs.

We understand the unique needs of your market – from consumer preferences to regulatory requirements – and we are committed to providing solutions that help you grow.

Conclusion

The right injection molding type can transform a good phone case into an outstanding product that resonates with consumers, complies with regulatory standards, and drives your business forward.

As a phone case purchaser, understanding these technologies can help you make wiser purchasing decisions and cooperate with phone case manufacturers that can keep their promises.

At YG, we are proud to be a phone case manufacturer that masters all the key injection molding processes. Whether you are launching a new product line or expanding an existing one, we are here to help you succeed.

Are you ready to take the next step? Please contact us today to apply for samples, get a custom quote, or discuss how we can turn your phone case ideas into reality.

.webp)