68% of importers overpay due to overlooked expenses in AirPods case production. This guide reveals cost-saving strategies for bulk buyers, with data-backed optimization methods.

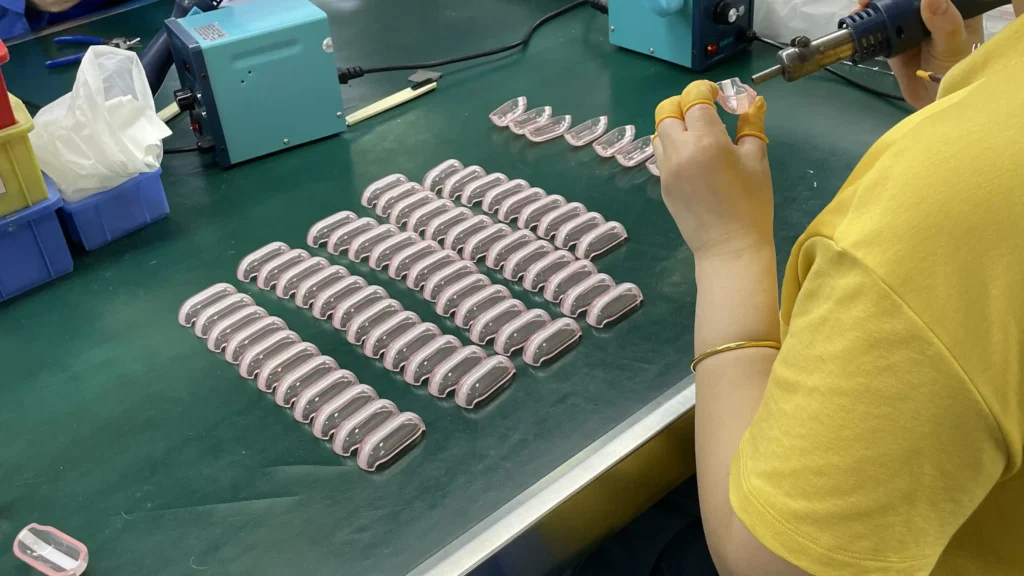

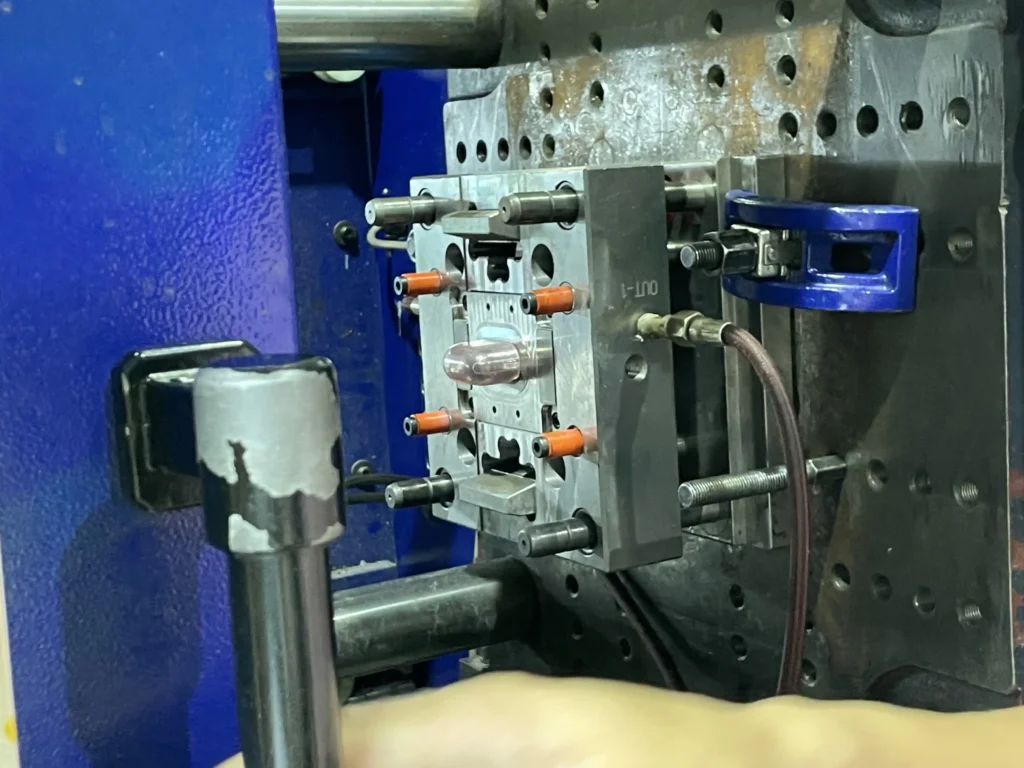

1. Mold Development Fees: The Silent Price Multiplier

Table of Contents

ToggleCustom molds decide 40% of AirPods case pricing—complex designs (e.g., dual-color injection) cost 3× more than single-color molds.

Key Tip:

- Ask suppliers if they offer multi-project mold sharing to amortize costs.

- Prioritize manufacturers with in-house mold engineering teams to avoid third-party fees.

2. Material Selection: Balancing Compliance & Profit

Eco-friendly materials add 15-20% cost but boost EU/US marketability. Compare options:

| Material | Cost (per 1k units) | Best For |

|---|---|---|

| Recycled TPU | $320 | Eco-conscious brands |

| Carbon Fiber | $950 | Luxury markets |

Key Tip:

- Request free material samples to test durability before bulk orders.

3. Certifications: Avoid Costly Compliance Errors

CE/FCC certifications add 1,200−1,200−2,500 per project. Non-compliance fines exceed $10k in EU markets.

Key Tip:

- Verify suppliers’ ISO 9001/14001 certifications to reduce audit risks.

- Confirm if they handle REACH and RoHS documentation for you.

4. Order Volume: Find Your “Golden Ratio”

Small batches (500- 2k units) cost 25% more per piece. Optimize with:

- Shared mold programs

- Mixed SKU production

Key Tip:

- Choose factories with 300k+ daily output capacity to avoid rush fees

5. Packaging & Logistics: Hidden Dragons

Retail-ready boxes save 18% logistics costs vs. standard packaging.

Key Tip:

- Demand flat-pack designs to maximize container space.

- Ensure drop-test reports for damage-proof shipping.

Conclusion & Next Steps

Controlling costs in custom AirPods case orders requires partnering with manufacturers who:

- Optimize mold investments through advanced engineering

- Guarantee compliance with pre-certified materials and processes

- Balance flexibility & scale in production planning

Why Clients Choose Us:

“YG acts as a true partner, not just a vendor. Their 10/10 communication and long-term vision eliminated 90% of our sourcing risks.”

— Verified Buyer from EU Consumer Electronics Brand

YG Differentiators:

- 40+ Mold Engineers: Reusable mold systems cut development costs by 35%

- 300k Daily Output: Industrial-Grade Capacity for Fast-Track Bulk Orders

- Zero Compliance Failures: ISO 9001/14001 + BSCI certified production

Ready to Streamline Your Order?

→ Contact YG

→ Email: info@yginno.com

→ WhatsApp: +86 186 7677 0798