As a B2B buyer or wholesaler in the U.S. and European markets, understanding the cost of injection molding is critical to maximizing your profit margins and negotiating effectively with manufacturers.

This guide breaks down the most impactful factors that shape production costs, helping you make data-driven decisions when sourcing phone cases. Whether you are a start-up or want to expand into the market of electronic technology accessories, knowing how these factors interact will empower you to balance quality, design, and budget.

Why Injection Molding Costs Matter for Your Phone Case Business

Table of Contents

ToggleInjection molding is the backbone of mass-produced phone cases, offering precision, scalability, and design flexibility that other manufacturing methods can’t match. For you, every dollar saved in production directly translates to higher competitiveness in retail pricing—especially in saturated markets like the U.S. and Europe, where consumers demand both quality and affordability. Let’s dive into the 9 critical factors that will help you optimize costs without compromising on your product vision.

The 9 Critical Factors Affecting Injection Molding Costs

1. Material Selection: Balancing Performance and Budget

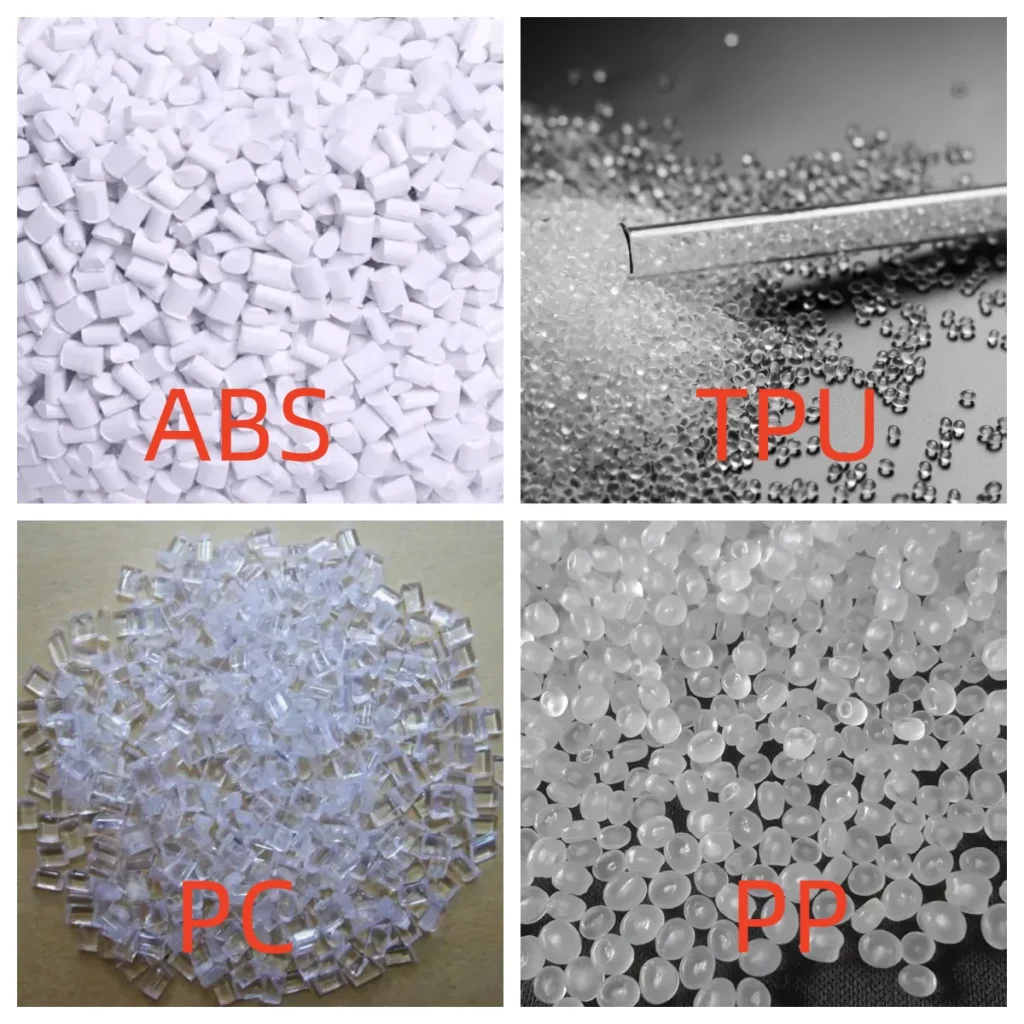

Your choice of material is the first and most impactful decision in controlling costs. Each material comes with its own price tag and performance trade-offs, so aligning your selection with your product’s target market is key:

| Material | Cost Range | Key Advantages | Best For |

|---|---|---|---|

| ABS | 1.20–1.20–2.00/kg | Moderate impact resistance, cost-effective for bulk orders | Mid-range, durable cases |

| PC | 2.50–2.50–3.50/kg | High clarity, heat resistance | Premium transparent cases |

| TPU | 1.80–1.80–2.80/kg | Flexible, shock-absorbent, affordable | Protective cases |

| PP | 0.80–0.80–1.20/kg | Lowest cost, lightweight | Disposable/promotional cases |

Pro Tip: Don’t overlook recycled material blends or material substitution—many phone case suppliers, including YG, can recommend alternatives that cut costs by 10-15% without sacrificing quality. For example, a 30% recycled TPU blend maintains flexibility while reducing raw material expenses.

2. Design Complexity: Simplify to Save

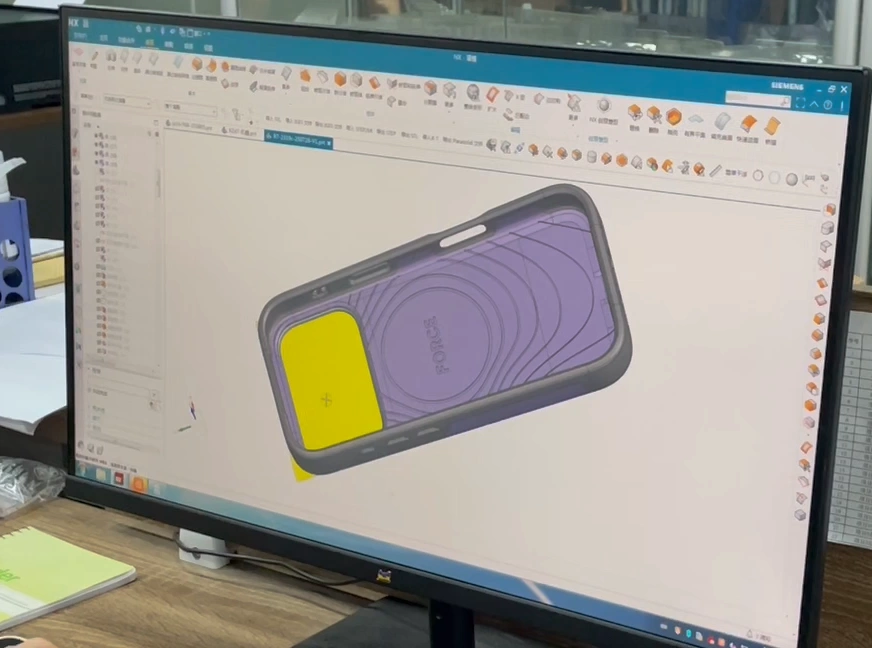

Intricate designs may look impressive, but they drive up costs at every stage of production. Features like multiple camera cutouts, 3D textures, or dual-color overmolding (e.g., TPU edges with a PC back) require more complex molds, longer cycle times, and higher labor input.

Here’s how complexity adds up: A basic single-color case with a flat back and standard camera cutout might cost $ 0.80 per unit to produce, while a case with a curved 3D surface, dual-material grip, and precision-fit card slot could jump to $ 2.50 per unit. The good news? Early design optimization can significantly reduce these costs. Work with your phone case manufacturers to simplify geometry—even small changes, like rounding sharp edges or reducing undercuts, can lower mold complexity and production time by 20-30%.

Pro Tip: Use 3D prototyping before finalizing your design. This allows you to test functionality and identify cost-heavy features (like unnecessary texture details) without investing in expensive molds.

3. Mold Tooling: The Hidden Cost Driver

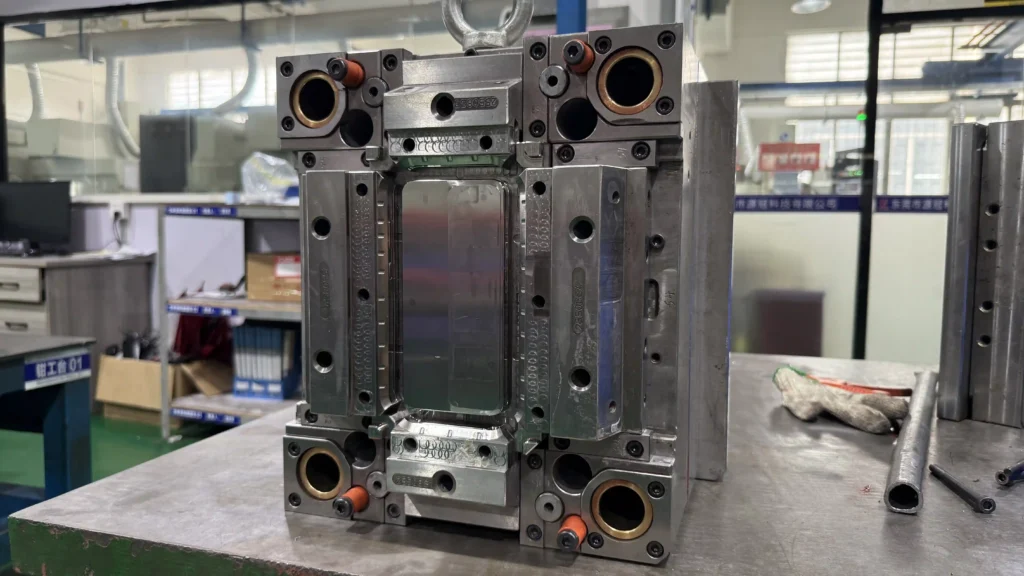

Molds are the single largest upfront investment in injection molding, often accounting for 30-50% of total project costs. Understanding what drives mold pricing will help you budget smarter:

- Cavity Count: A single-cavity mold costs less upfront (1,000–1,000–3,000 for aluminum) but produces only one case per cycle. A 4-cavity mold, by contrast, costs 3x more but quadruples output—critical for high-volume orders.

- Mold Material: Aluminum molds are cheaper and faster to produce but wear out after 10,000-50,000 cycles, making them suitable for short runs. Steel molds (5,000–5,000–15,000+) last 100,000+ cycles, ideal for long-term production.

- Lifespan: Always ask, “How many cycles is this mold rated for?” A steel mold for a best-selling case might seem expensive now, but it will pay off when you’re producing 100,000+ units over two years.

Pro Tip: If you’re testing a new phone case design, start with a single-cavity aluminum mold to validate market demand. Once sales take off, invest in a multi-cavity steel mold to scale efficiently.

4. Production Volume: The Power of Scale

Injection molding thrives on volume—higher production runs drastically reduce per-unit costs by spreading fixed expenses like mold tooling across more units. Let’s put this in perspective:

| Production Volume | Mold Cost per Unit | Total Unit Cost |

|---|---|---|

| 1,000 units | $5.00 | 8–8–10 |

| 10,000 units | $0.50 | 3–3–5 |

| 100,000 units | $0.05 | 1.50–1.50–3 |

Negotiation Strategy: Lock in volume discounts with your supplier. Many manufacturers, including YG, offer tiered pricing—for example, 5% off orders over 50,000 units or 10% off for annual commitments. If you’re unsure about demand, consider phased orders (e.g., 20,000 units now, 30,000 units in 3 months) to reach cost-saving thresholds without overcommitting inventory.

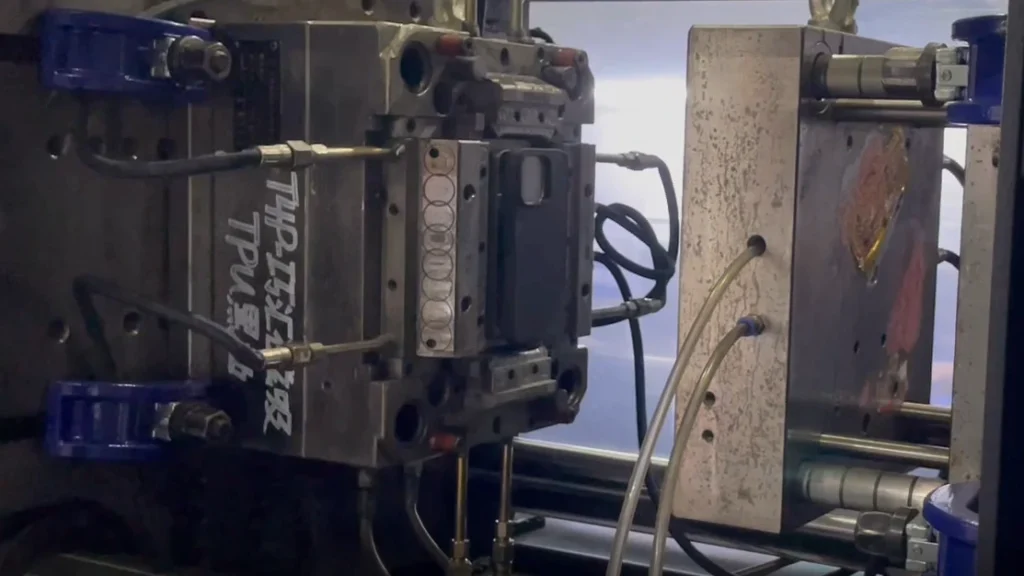

5. Injection Cycle Time: Speed Up to Cut Costs

Cycle time—the time it takes to produce one batch of cases—directly impacts hourly output. A shorter cycle time means more units per hour, lower labor costs, and faster time-to-market. For example, a cycle time of 30 seconds produces 1,440 cases per day, while a 45-second cycle drops that to 960 units—a 33% reduction in productivity.

Mobile phone cover suppliers optimize cycle time by:

- Using high-efficiency injection machines with faster clamp speeds.

- Designing molds with advanced cooling systems to reduce part solidification time.

- Simplifying mold ejection mechanisms to minimize downtime between cycles.

Pro Tip: Ask your supplier, “What’s the cycle time for my design?” A reputable manufacturer like YG can often reduce cycle times by 10-15% through mold optimization, adding thousands of units to your monthly output at no extra cost.

6. Labor and Expertise: Skilled Teams Reduce Waste

Labor costs vary dramatically by region, but skilled technicians are worth the investment—they minimize defects, optimize machine settings, and keep production running smoothly. In the U.S. and Europe, where labor rates are high, many buyers outsource to Asia to cut costs. However, cheaper labor doesn’t always mean better value: A factory with unskilled workers might have a 5% defect rate, while a skilled team (like YG’s) keeps defects below 1%, saving you from costly rework or returns.

Key Question to Ask: “What is your average defect rate, and how do you train your operators?” A 2% defect rate vs. 5% can save you $10,000+ on a 100,000-unit order—money better spent on marketing or product innovation.

7. Secondary Processes: Add-Ons That Add Up

Post-production steps like painting, silk-screening, or packaging can add 0.50–0.50–2.00 per unit to your costs. While some finishes are essential (e.g., UV coating for scratch resistance), others may be unnecessary for your target market. Here’s how common secondary processes impact your budget:

| Secondary Process | Cost per Unit | Use Case | When to Skip |

|---|---|---|---|

| Silk-screening | 0.20–0.20–0.50 | Logos/branding on basic cases | If using in-mold labeling (IML) instead |

| UV coating | 0.30–0.30–0.70 | Scratch resistance for transparent PC cases | For matte or textured TPU cases (already scratch-resistant) |

| Custom packaging | 0.50–0.50–1.50 | Premium retail presentation | For bulk wholesale orders (use generic packaging) |

| Laser engraving | 0.40–0.40–0.90 | Unique serial numbers or high-end branding | For low-cost promotional cases |

Pro Tip: Replace silk-screening with in-mold decoration (IMD/IML) to combine decoration and molding in one step. This eliminates separate printing costs and reduces labor by 20%. For example, a logo embedded during molding costs 0.10 per unit 0.10perunitvs.0.30 for post-production silk-screening.

8. Quality Control and Testing: Invest to Avoid Losses

Cutting corners on quality control might save money upfront, but it leads to costly returns, damaged brand reputation, and wasted materials. For phone cases, key tests include:

- Drop testing: Ensures TPU/protective cases withstand impacts (e.g., 4-foot drops onto concrete).

- Dimensional accuracy: Verifies fit for specific phone models (e.g., iPhone 15 vs. Samsung Galaxy S24).

- UV resistance: Prevents TPU yellowing or PC discoloration under sunlight.

- Adhesion testing: For multi-material cases (e.g., TPU-PC hybrids) to avoid delamination.

A reputable supplier like YG includes basic QC in their quotation, but advanced testing (e.g., 1,000-cycle drop tests) may cost extra. However, the investment pays off: A 1% defect rate on a 100,000-unit order could cost 5,000inreturns, while rigorous testing reduces defects to 0.14,500.

Pro Tip: Ask suppliers for certifications (e.g., ISO 9001) and sample test reports to verify their QC standards.

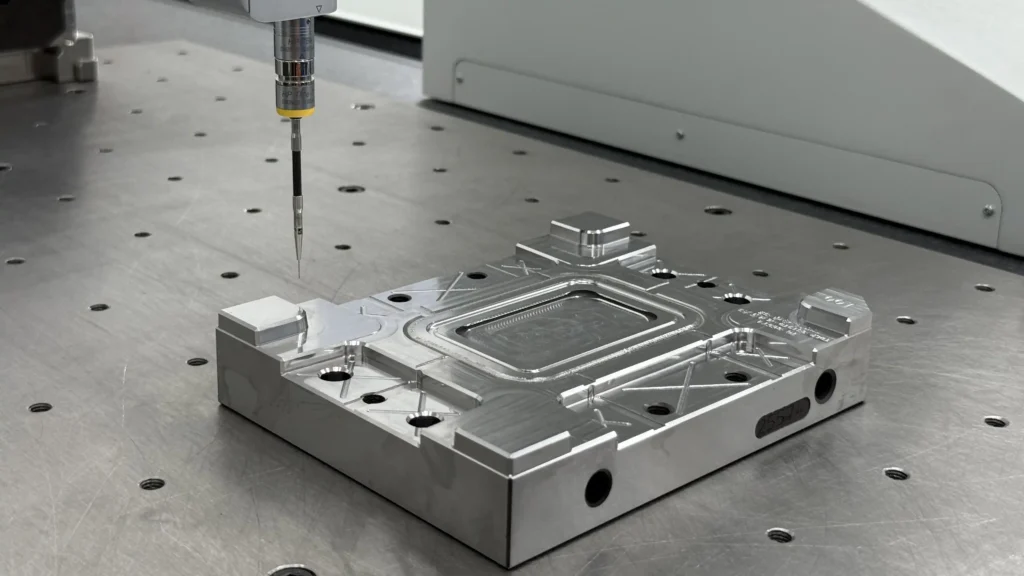

Measure the accuracy of the mobile phone case tooling using a three-coordinate measuring instrument

9. Manufacturer Location: Logistics, Tariffs, and Lead Times

Where your supplier is based impacts costs beyond production alone. For U.S. and European buyers, balancing overseas manufacturing savings with logistics expenses is critical:

- Asia (China, Vietnam): Lower labor and material costs reduce production expenses by 30–50%, but shipping adds 0.30–0.30–1.00 per unit, and lead times stretch to 4–6 weeks .

- Europe: Faster delivery (1–2 weeks) and no import tariffs, but production costs are 2–3x higher due to labor rates.

- U.S.: Ideal for small-batch, quick-turnaround orders, but high labor costs make large runs impractical.

Example: A 100,000-unit order from China might cost 1.50perunit(production)+1.50perunit(production)+0.50 (shipping) = 2.00total.AEuropeanmanufacturercouldcharge2.00total.AEuropeanmanufacturercouldcharge3.50 per unit but eliminate shipping costs, making it better for orders under 20,000 units.

Pro Tip: For high-volume, standard designs, Asian suppliers like YG offer the best value. For custom, low-volume orders, pair Asian mold production with European assembly to split costs.

How to Lower Injection Molding Costs: Actionable Strategies

Now that you understand the factors driving costs, here are 5 proven strategies to optimize your budget:

Optimize designs early: Use 3D prototyping to simplify geometry and reduce mold complexity.

Leverage volume discounts: Negotiate tiered pricing (e.g., 5% off for 50,000+ units) or annual contracts.

Combine processes: Replace secondary steps (e.g., painting) with in-mold decoration.

Choose multi-cavity molds: For volumes over 50,000 units, a 4-cavity mold cuts per-unit costs by 40%.

Partner with experienced suppliers: YG’s 20+ years in B2B phone case manufacturing means access to optimized material blends, efficient molds, and streamlined logistics for U.S. and European markets

FAQ: Your Plastic Injection Molding Cost Questions Answered

1,000–3,000 for simple aluminum molds (10,000-cycle lifespan); 5,000–5,000–15,000+ for steel molds (100,000+ cycles)

Only for niche designs—unit costs drop 50%+ at 10,000+ units due to the cost-sharing of molds.

Yes—use a 20–30% recycled TPU blend. It maintains shock absorption while cutting material costs by 15%

Partner with YG: Your Trusted Injection Molding Partner

When it comes to optimizing custom injection molding cost for phone cases, partnering with an experienced manufacturer like YG delivers tangible savings. Our specialized design and engineering expertise streamlines production, ensuring cost-effective solutions tailored to U.S. and European B2B buyers.

Why Choose YG?

1. Design Optimization

Our in-house design team transforms concepts into a cost-efficient reality. We simplify geometries, reduce unnecessary features, and engineer for manufacturability—cutting mold costs and production time by up to 30%.

2. Expert Mold Engineering

Our veteran mold engineers create high-precision tools tailored to your volume: single-cavity molds for small runs or multi-cavity steel molds for high-volume production. With 35-day lead times and DFM analysis, we avoid costly revisions.

3. Rigorous Quality Control

ISO-certified processes ensure <0.5% defect rates (industry avg: 2-3%). In-line inspections, drop testing, and UV resistance checks guarantee reliability.

4. One-Stop Service

YG offers ODM solutions from phone case design to delivery. We handle design, mold making, injection molding, and logistics—so you focus on growing your business.

Ready to Reduce Costs? Let’s Connect→

Get a free DFM analysis and quote today.

.webp)