Have you ever opened a batch of phone cases and found wavy lines on the transparent PC models or small black dots on the edges of the TPU? As a buyer or retailer of phone cases, these injection molding defects are not only annoying – they can also lead to overstocked inventory, customer returns, and damage to trust in your brand.

As a top Chinese phone case manufacturer, we know how important it is to prevent these defects before they reach your warehouse. We align this guide with industry best practices (such as those outlined in the quality control framework) to break down 11 common problems, why they occur on your phone case, and the step-by-step repair methods you can request from your supplier. Let’s get started.

Why Injection Molding Defects Matter for Your Phone Case Business

Table of Contents

ToggleInjection molding is the pillar of mobile phone case production, but it is also where costly mistakes occur. Batches with groove marks may make your customers feel unprofessional. Deformed cases that are not suitable for mobile phones? They will be sent back soon. Even minor issues, such as color stripes, can disrupt the consistency of your brand’s product line.

What’s the good news? Common injection molding defects can be prevented. By understanding injection molding defects and causes (and how reliable manufacturers solve them), you can avoid the headache of wasting time, money, and reputation. So, let’s delve into the three main categories of defects that affect phone cases.

Part 1: Injection Molding Defects and Solutions Arising from Process Errors

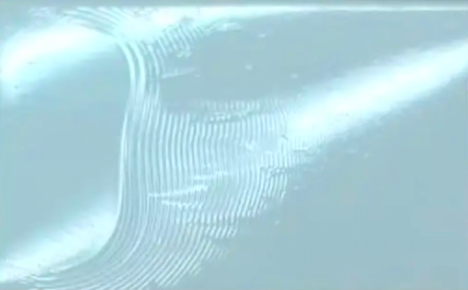

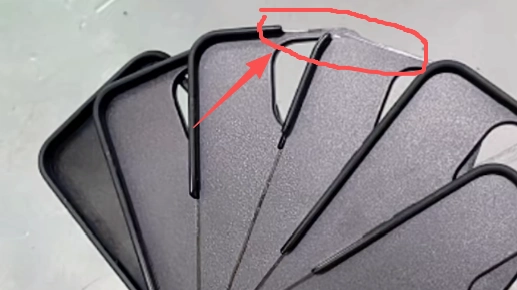

1. Flow Lines (Wavy or Ring-Shaped Marks)

Flow lines are displayed as a wavy pattern and usually changes color slightly compared to other parts. They are most commonly found in narrower areas – think of the thin edges around the button cut or the thin edges of the camera frame. Sometimes, they look like ring-shaped bands near the “gate” of a mold (where molten plastic enters the mold).

They won’t damage the protective case, but they will damage the high-end transparent PC protective case – just like the high-end models your customers like. So, why did they appear in your order?

Under normal circumstances, the flow lines come from uneven cooling: when molten plastic flows through the mold, some parts cool down faster than others. The difference in wall thickness (such as a thick backplate beside a thin frame) will make the situation even worse. Slow injection speed also has an impact – if the plastic starts to harden before filling the mold, it will leave those wavy marks.

- Increase the injection speed, pressure, and material temperature to ensure that the plastic is fully filled in the mold before cooling.

- Round the corners of the mold (increase the wall thickness) to maintain consistent flow.

- Reposition the gate of the mold to increase the distance between it and the coolant (this can prevent the plastic from cooling too early).

- Slightly increase the nozzle diameter to accelerate the flow rate and prevent premature hardening.

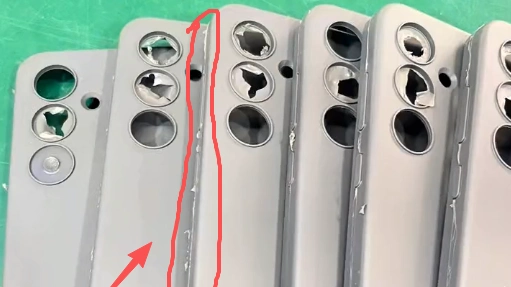

2. Burn Marks (Black or Rust-Colored Spots)

Burn marks are what they sound like: dark, discolored spots on the edge or surface of a phone case. This kind of mark usually appears on the edge of the TPU case or on the inner support ribs in the rough design. Although they rarely weaken the strength of the case, they do make your product look cheap – and this may not be what your customers expect.

What causes this situation? It might be air trapped in the mold or overheated resin. When you inject plastic too quickly, air will be squeezed into tiny gaps and overheat. Excessively high melting temperatures may also cause the resin itself to burn, leaving those unsightly little spots.

- Reduce the melting and mold temperatures to prevent overheating (this is particularly important for heat-sensitive materials like TPU)

- Slow down the injection speed – this can reduce the risk of air being trapped in narrow areas such as camera cuts.

- Expand the vent and gate of the mold to allow the trapped air to escape before it is heated.

- Shorten the mold cycle time – the shorter the time spent in the mold, the less chance the air or resin will overheat.

3. Warping (Bent or Twisted Cases)

You can imagine it as wood: if the wood is not dried evenly, it will warp. The same is true for plastics. When different parts of a phone case cool at different rates, the material will contract unevenly, causing the case to deform. This situation is relatively common in PC cases, where the thicker parts (such as reinforced corners) cool down more slowly than the thinner parts (such as frames).

Other culprits? Excessively high temperatures or the low thermal conductivity of plastics – both of these can exacerbate the uneven cooling situation. Poor mold design (inconsistent wall thickness) may also cause warping.

- Make sure the cooling process is gradual and long enough – this allows the plastic to shrink evenly without pressure.

- Reduce the temperature of the material or mold to slow down cooling and minimize uneven shrinkage.

- Switch to materials with a lower shrinkage rate (choose PC with a shrinkage rate of ≤0.5% for the phone case).

- Redesign the uniform wall thickness and symmetry of the mold, which ensures consistent cooling throughout the entire situation.

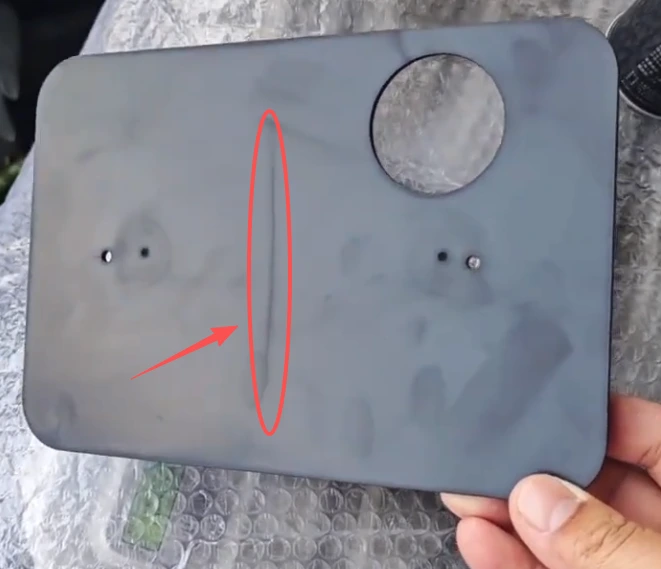

4. Vacuum Voids / Air Pockets

Vacuum voids refer to the tiny air bubbles trapped inside a phone case, most obvious in transparent polycarbonate or light-colored TPU material phone cases. These bubbles may seem unprofessional, but they are not merely an aesthetic issue: they can weaken the strength of the phone case, making it more likely to burst when dropped.

The quality control team usually marks the gaps as “minor”, but for phone cases that rely on durability, they are a risk. So, why do voids form?

The main reason lies in insufficient injection pressure – if the pressure is not high enough, the trapped air cannot be pushed out of the mold cavity. Sometimes, the plastic near the mold wall cools down too quickly, causing it to harden and pull the internal material inward, thus forming bubbles. In thicker case parts (such as anti-drop corners over 6 millimeters thick), it is also more difficult to avoid voids.

- Increase the injection pressure to expel the trapped air from the mold before the plastic hardens.

- Choose low-viscosity materials (such as TPU with a melt index of 15-20g/10min)- this makes it easier to flow and reduces air retention.

- Place the gate of the mold close to the thickest part of the phone case – this can prevent premature cooling that is most likely to form in the gap.

- Pre-dry the materials (PC requires 4-6 hours at 120-140°C; TPU requires 2-3 hours at 80-100°C) to remove the moisture that may form bubbles

5. Sink Marks (Small Depressions)

- Increase the holding pressure and time – this will push more plastic into the mold as the inner layer material shrinks and fills potential dents.

- Extend the cooling time to harden the outer plastic layer before the inner material shrinks too quickly.

- Design the mold with thinner case walls (most phone cases are kept under 2 millimeters)- thinner walls cool down faster and shrink less.

- Add cooling channels near thick sections (such as marking areas) to accelerate cooling and reduce shrinkage.

6. Weld Lines (Hair-Like Streaks)

Weld lines appear at the point where two streams of molten plastic converge in the mold, just like the situation where the plastic on the back of the case is drilled around the camera and converges to the other side. They look like tiny, hair-like stripes. Although not obvious, they weaken the strength of the case: for instance, if the TPU phone case is bent, it may break at these lines.

Why do they form? When two plastic streams meet, they need to be kept at a high enough temperature to bond. If they cool down too much before converging, they will partially solidify and thus fail to stick together well, leaving that fragile visible line.

- Raise the material temperature to keep the plastic in a molten state when the streams meet – this ensures a strong bond.

- Increase the injection speed and pressure to limit the cooling of the plastic before it is filled in the mold. Redesign the mold to eliminate the partitions that separate the plastic flow (such as unnecessary support ribs near the camera cut)

- Switch to a material with a lower melting point or viscosity – this way, it will flow faster and remain at a high temperature for a longer time, thereby enhancing the bonding force.

7. Jetting (Squiggly Lines)

Jetting marks on the surface of the case are manifested as twisted and curved lines, usually starting from the entrance of the mold. This phenomenon is more common in light-colored silicone or polycarbonate cases. Although this is mainly an aesthetic issue, it may also indicate weak points in the material.

The main reason lies in the excessively high injection pressure: when plastic is forced through a narrow gate under high pressure, it will “spray” into the mold instead of gradually flowing. This initial “jetted” plastic will cool and harden on the mold wall – then, as more plastic flows in, it will lift the already hardened part, leaving a curved mark.

- Reduce the injection pressure to prevent plastic from being sprayed into the mold – slow and steady flow is key.

- Increase the temperature of the materials and molds to prevent the plastic from hardening prematurely during the initial injection.

- Design the mold with the gate positioned to guide the plastic flow on the mold (rather than along the length)- this can evenly distribute the flow and avoid jetting.

- Slightly expand the gate to reduce the pressure required to push the plastic into the mold.

Part 2: Injection Molding Defects and Solutions Related to Material Use or Storage

8. Discoloration (Color Streaks)

Discoloration (or “color streaking”) usually occurs when the phone case does not match the sample – some may be yellowish, some are relatively light, and some have randomly distributed mottled streaks. This situation can be described as a disaster for those brands that rely on a unified brand image.

What could be the cause? Resin residues from the previous color batch remaining in the hopper or nozzle are a common cause. Unevenly mixed masterbatches (i.e., concentrated colorants added to the raw plastic) may also cause streaks. Sometimes, the thermal stability of this colorant itself is poor – it will decompose at high molding temperatures, thereby causing fading or discoloration.

- Make sure that the supplier thoroughly cleans the hopper, nozzle, and mold between color changes – no residual resin means no streaks.

- Let them use the empty compound to remove the excess color on the machine, and then start a new run.

- Select colorants with sufficient thermal stability (look for colorants that can withstand temperatures of 260 ° C or higher for PC casings).

- Ensure that the masterbatch is evenly mixed with the raw plastic – use a twin-screw mixer to achieve a consistent color distribution.

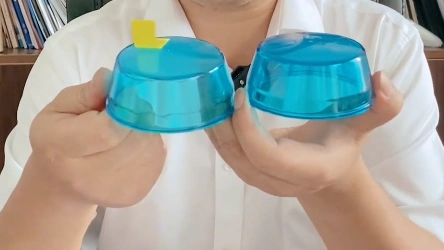

9. Delamination (Peeling Layers)

Delamination refers to the peeling of the surface layer of a phone case, just like the peeling of paint. This is a serious defect because it undermines the protective function of the case and makes it look cheap. For sturdy or multi-layered case structures (such as PC+TPU hybrid materials), delamination is an intolerable issue.

The most common cause is material contamination: if your supplier mixes incompatible plastics (such as ABS and PP) or incorporates foreign substances into the raw materials, then the layers cannot bond. Excessive moisture in the material (resulting from poor storage conditions) may also damage the adhesion between layers. Even an excessive amount of mold release agent (used to help remove the product from the mold) may cause peeling.

How to fix it:

- If the problem is moisture, please ask the supplier to pre-dry the material correctly (with a target humidity of ≤0.05%) or increase the temperature of the container.

- Make sure they store and handle resin particles carefully – keep them in sealed containers to avoid contamination.

- Ask them to limit the use of mold release agents or switch to internal mold release agents (added to the plastic itself) instead of spraying alcohol on the mold.

- Let them use infrared spectroscopy to test the purity of the material – this can detect incompatible plastics or debris before molding.

Part 3: Injection Molding Defects and Solutions Caused by Poor Mold Design or Maintenance

10. Short Shot (Incomplete Cases)

Short shot refers to the situation where the molten plastic fails to fully fill the mold – your product may have missing corners, incomplete camera frames, or gaps at the edges. These products are 100% unsalable and waste materials and time.

What causes these problems? The main problem is restricted flow: narrow or clogged gates may prevent plastic from reaching all parts of the mold. Sometimes, if the material is too viscous (thick) or the mold is too cold, both of these can cause the plastic to harden before filling the cavity. In addition, the air caused by the air may also impede the flow, thereby affecting the integrity of the filling.

How to fix it:

- Redesign the mold to use wider channels or gates – this enables the plastic to flow freely to all parts of the case.

- Increase the injection speed or pressure to push the plastic through the narrow section before it cools down.

- Increase the mold temperature to prolong the melting time of the plastic – this is particularly important for high-viscosity materials like PC

- Add additional exhaust ports (or expand the existing ones) to allow the trapped air to escape – no air blockage means complete filling.

11. Flash (Burrs or Thin Protrusions)

Flash (also known as “burrs” or “spills”) is excess plastic that seeps out from the gaps in the mold. You may find it at the fine edges of the case, around button holes, or near the door edge. This phenomenon is usually not obvious, but it may scratch the phone or get stuck in the pocket. Removing flash will increase additional labor costs, and if not handled properly, it will also leave rough edges.

The main reason is a poorly designed or severely worn mold: if the mold plates do not fit tightly (due to wear or manufacturing defects), plastic will seep out from the gaps. Excessively high injection pressure or mold temperature may also force plastic to overflow from tiny Spaces.

How to fix it:

- If the mold is worn or misaligned, ask the supplier to reprocess or design it – a closely fitting plate means no plastic can escape.

- Increase the clamping force of the mold – this will press the plates tightly together, confining the plastic within the mold cavity.

- Adjust the mold temperature and injection pressure – reducing both can decrease the amount of plastic overflow.

- Have them regularly inspect the molds (after every 100 cases) to detect problems such as wear and tear at an early stage and prevent major flash issues in the later stage.

Cooperate with A Reliable Phone Case Manufacturer to Avoid Injection Molding Defects

You don’t have to manage plastic injection molding defects separately. A quality-oriented phone case manufacturer will integrate prevention into every step – here are your requirements:

1. Raw material inspection: They will test the purity, moisture content, and thermal stability of each batch of PC, TPU, or silicone. Materials without pollution or moisture mean fewer defects in injection molding.

2. Process inspection: They will conduct a “100-piece inspection” – for every 100 pieces produced, 5 pieces will be inspected to check the assembly line, sinking marks, or warping. This way, problems can be captured as early as possible before they become a complete batch of defects.

3. Mold maintenance: They will clean and inspect the mold after each run, repair wear and tear, and ensure a tight fit. Well-maintained molds have a longer lifespan and can produce consistent products.

4. Final test: Each phone case has a suitable test (using a real phone) and visual inspection for defects. Only products that meet your requirements will be dispatched.

At YG, we keep the defect rate below 0.5% because we know that your success depends on consistently high-quality phone cases.

Conclution

Common injection molding defects – whether caused by process errors (such as flow marks or warping), material issues (such as discoloration or delamination), or improper mold maintenance (such as short shot or flash) – can put your phone case business in a difficult situation, leading to returns, inventory waste, and damaged brand trust in the European and American markets.

What is the key point? Most defects in injection molding can be avoided through targeted repair measures: optimizing the injection speed and pressure of the PC/TPU case, pre-drying the material to prevent bubble formation, and keeping the mold clean to eliminate flash.

As a phone case manufacturer dedicated to quality, we have turned these repairs into standard practices – from raw material inspection to process inspection – keeping the defect rate below 0.5%. If you are ready to skip the trouble of defective batches and get consistent, saleable phone cases, contact us immediately